Based on Learn-Digital own LD-ML Framework, developed and perfected over 15 years, based on open source software (PHP + MySQL)

Where does Learn-Digital come into play?

ERP software market is a large worldwide market dominated by a few brands (SAP first). For smaller businesses, there are a few key players like Kingdee/K3 and UFIDA in China which also dominates the market. LD-ERP has cut itself a strong niche thanks to its unique capacity for customization. By being a software entirely written in house, it is extremely easy for our programmer to adapt (database fields, process and languages) to your own business reality, with prices in the lowest end of the spectrum. We provide by default:

- Perpetual license for at least 1 server (running in more require additional license)

- Source Code is offered to the client in the license (with only limit not to resell)

- Dual language always included in the default license (English and Chinese), with the possibility to add more.

- Our framework is very special, not only the interface is fully multi-lingual, but also the data can be defined as multi-lingual. For instance, multi-language field appear in correct language when the selection is applied, and on printed documents as well.

- Technically we support any kind of Linux installation (Debian, Ubuntu, CentOS), although we tend to prefer Debian based; PHP version from 5 to 7.x supported, with guaranteed support for future versions; MySQL open version (MariaDB) is supported.

Manufacturing ERP Solution is just:

- A specific set of pre-packed modules that can accomplish the most common task of your manufacturing business.

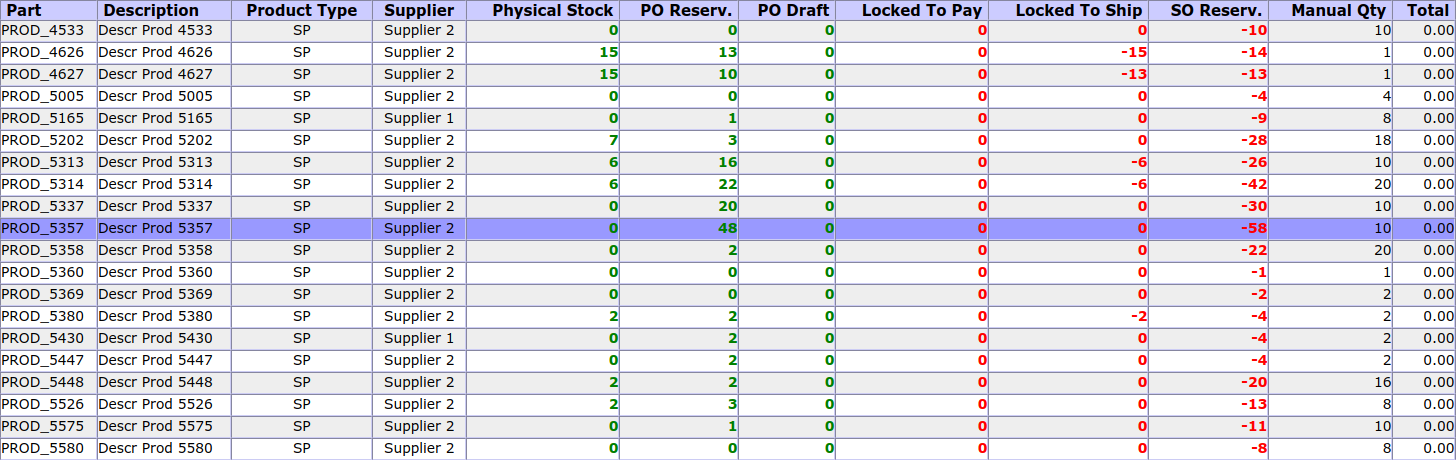

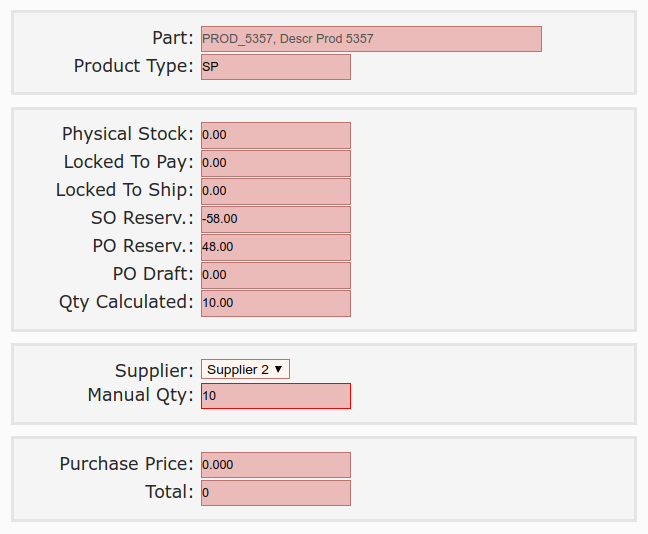

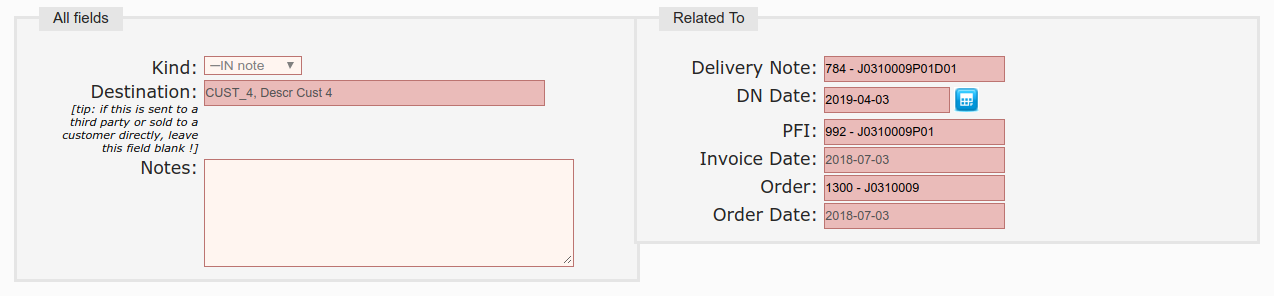

- Standard included modules are: Warehouse (including multiple warehouses and locations), Product & Parts Labelling, Purchasing, Sales, Processing, Manufacturing orders (with MRP), BoM, Accounting (* only the direct costs and eventual BoM operational costs), Basic Data, Companies Database, User Administration, Rich Reporting functionality, Real Time and Historical Charts.

- [optional] Barcode sub-system:

- Full traceability solution, with barcode generation, printing and scanning.

- Setting rules of lot distribution (FIFO, first in first out, like in case of food industry, or based on other programmable rules).

- Launching statistics and easy recall campaigns in case a defective lot is found within the supply or manufacturing chain.

- [optional] MES (Manufacturing Execution Software) sub-system:

- Provide inside traceability solution (from the moment parts leave warehouse until the moment they come back as finished or semi-finished goods).

- Design your own processes/sub-processes

- Setting up interaction with sensors, PLC or operators in the workshop area, in order to define advancing rules for your materials.